Canon u.s.a.,inc. Shall not be held liable for errors contained herein, or for lost profits, lost opportunities, consequential or incidental damages incurred as a result of acting on information, or the operation of any software, included in this software site.

Service Manual Canon imageRUNNER Advance 4251 imageRUNNER Advance 4245 imageRUNNER Advance 4235 imageRUNNER Advance 4225;

This manual is in the PDF format and have detailed Diagrams, pictures and full procedures to diagnose and repair your Canon copier.

You can print, zoom or read any diagram, picture or page from this Service Manual. Every chapter on this manual is fully detailed and contain all the simulation codes, trouble codes, maintenance procedures, reset procedures, diagnose procedures of Canon photocopier. You can find easily everything what do you need.

To see what contain, please read table of contents:

0. Safety Precautions

CDRH Act

Laser Safety

Handling of Laser System

Turn power switch ON

Safety of Toner

About Toner

Toner on Clothing or Skin

Notes When Handling the Lithium and Ni-MH Batteries

Notes Before it Works Serving

Points to Note at Cleaning

Notes On Assembly/Disassembly

1. PRODUCT OVERVIEW

Product Lineup

Main Body

Pickup/Delivery System Option

Applicable Option for Each Model

Required Options/Conditions

Scanning System Options

Required Options and Conditions

Function Expansion System Options

Required Options and Conditions

Feature

Product feature

Service Features

Service Mode

Improved Upgrading Operability

Jam/Error Code Display Specifications

Specifications

Product Specifications

Weight and Size

Productivity (Print speed)

iR ADVANCE 4251

iR ADVANCE 4245

iR ADVANCE 4235

iR ADVANCE 4225

Paper Type

External View/Internal View

External View

External Cover

Cross Sectional View

Operation

Power Switch

Types of power switch

Points to Note on Turning ON/OFF the Power Switch

Control Panel

Control Panel

Main Menu

Settings/Registration Menu

2. TECHNOLOGY

Basic Configuration

Functional Configuration

Original Exposure System (Reader)

Features (Reader)

Specifications (Reader)

Specifications

Names of Parts (Reader)

External View

Cross Section

Major Components

Reader Relay PCB

Controls (Reader)

Basic Sequence

Controlling the Scanner Drive System

CCD Unit

Enlargement/Reduction

Detecting the Size of Originals

Dirt Sensor Control

Image Processing

Color offset correction in sub scanning

Servicing (Reader)

Periodically Replaced Parts

Consumable Parts

Periodical Servicing

Action to take when replacing parts

Major Adjustments

Troubleshooting

Main Controller

Overview

Features

Specifications/configuration

Boot/Shutdown sequence

Controls

Flow of Image Data

Security features (encryption key and certificate, password protection)

Option HDD

HDD mirroring feature (option)

Removable HDD (option)

HDD Data Encryption & Mirroring Kit (option)

Service Operations

HDD

Main Controller PCB 1

Main Controller PCB 2

TPM PCB

Laser Exposure System

Overview

Specifications/Controls/Functions

Main Configuration Parts

Control System Configuration

Various Controls

Overview

Controlling the Laser Activation Timing

Controlling the Intensity of Laser Light

Controlling the Polygon Motor

Controlling the Laser Shutter

Work of the service

Scheduled Servicing

Measures in the Parts Replacement

Adjustment

Troubleshooting

Image Formation System

Overview

Features

Specifications

Major Components of Image Formation System

Image Formation Process

Basic Sequence

Sequence of Operation (initial rotation)

Sequence of Operation (printing)

Sequence of Operation (last rotation)

Controls

Image Stabilization Control

Drum Unit

Developing Assembly

Toner cartridge

Transfer Unit

Waste toner container

Servicing

Periodically Replaced Parts

Consumable Parts

Periodical Servicing

Action to take when replacing parts

Major Adjustments

Troubleshooting

Fixing System

Overview

Features

Specifications

Major parts configuration

Controls

Fixing temperature control: overview

Standby temperature control

Print temperature control

Down sequence control

Fixing pressure roller cleaning sequence

Fixing film edge cooling control

Paper loop amount control before fixing

Protection features

Work of Service

Periodical ServicePeriodical Service

Consumable Parts

Periodical Servicing

Action to take when replacing parts

Major Adjustments

Troubleshooting

Pickup Feed System

Overview

Overview

Specification

Parts Configuration

Arrangement of Sensors

Diagram of Paper Paths

Controls

Overview

Cassette Pickup Assembly

Multi-Purpose Pickup Assembly

Fixing / Registration Assembly

Duplex / Delivery Assembly

Detecting Jams

Work of Service

Maintenance service

Periodically replaced parts

Consumable parts

Periodically Servicing parts

Action to take when replacing parts

Major Adjustments

Troubleshooting

External Auxiliary System

Overview

Power Supply Configuration

Controls

Energy saver function

Conditions for Not Entering Deep Sleep

Quick Startup

Heater control

Fan Control

Counter control

Restricted function

Servicing

Periodically Replaced Parts

Consumable Parts

Periodical Servicing List

Action to take when replacing parts

Major Adjustments

Troubleshooting

MEAP

Preparation for Using SSO-H

Outline

Domain authentication management

PC environment of administrator users and general users

Preparation for Using SMS

Preparation of PC for Accessing SMS

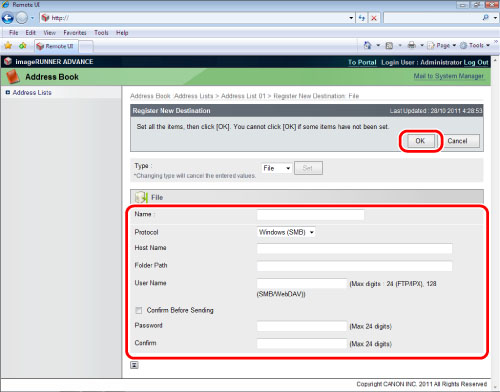

Settings on the Device Side

How to Check the Serial Number

Login to SMS

Outline

When SMS Cannot Be Accessed

How to Deal with a Message “Certificate Error” That Appears at the Time of

Access

Installing an MEAP Application

Outline

Procedure to install applications

Resource Information

About MEAP Application Management Page

MEAP Specifications

What is MEAP Specifications (MEAP Spec Version)?

MEAP Application Management

Outline

Starting, Stopping, or Uninstalling the MEAP Application

Managing the License File

Other License File Management Functions

Enhanced System Application Management

Outline

About Login Service

Default Authentication overview

SSO-H (Single Sign-On-H) overview

Local device authentication

Server authentication (Active Directory authentication)

Server Authentication (LDAP Authentication)

Server authentication and local device authentication

Steps to Change Login Services

Login Service Installation Procedure

Login Service Uninstallation Procedure

System Application Management

Password authentication

RLS Authentication

Setting the method to login to SMS

Outline

Initial Display Languages of SMS

System Information

Outline

Checking the System Information

Display of System Information Details

Printing the System Information of a MEAP Application

Content of MEAP system information

MEAP Application Information

Outline

Procedure to Check MEAP Application Information

Check License

Outline

Procedure to Check the License File

Changing SMS Login Password

Outline

Procedure to Change the SMS Login Password

MEAP Application Setting Information Management and Log

Management

Outline

Advantages Obtained When Using the Services

MEAP Application Setting Information Management

MEAP Application Log Management

Maintenance

Backup of the MEAP Application Area and Recovery of the Backup Data Using

SST

Formatting and Replacing the HDD

MEAP Safe Mode (level 2)

Collection of MEAP Console Logs

Using USB Devices

Integrated Authentication Function

Points to Note When Enabling the [Quick Startup Settings for Main Power]

Setting

Remedy to Be Performed When the Device Has Become Unable to Be

Logged in

Reference material

Glossary

Option for exclusive individual measure

Embedded RDS

Product Overview

Overview

Features and benefits

Major Functions

Limitations

Service Mode Menu Transmission Function

Service cautions

E-RDS Setup

Confirmation and preparation in advance

Steps to E-RDS settings

Steps to Service Browser settings

Initializing E-RDS settings

FAQ

Troubleshooting

Error code and strings

Updater

Overview

Outline

Installing MEAP Application/System Option

System Configuration

List of Functions

Distribution Flow

Limitations and Cautions

Limitations

Cautions

Preparation

Overview of Preparation

Setting Sales Company’s HQ

Network Settings

Enabling UGW Link

Enabling [Update Firmware] Button of User Mode

Enabling [Install Application/Options] Button of User Mode

Enabling [Manual Update] Button of User Mode (Remote UI)

Enabling [Scheduled Update] Button of User Mode

System Management Operations

Various Setting

Displaying Logs

Communication Test

Maintenance

Upgrading Updater

Formatting Hard Disk

How to Replace Controller Boards

How to Replace Devices

FAQ

FAQ on Installing Firmware

FAQ on the Local CDS Operation Environment

FAQ on Installing MEAP Application/System Option

FAQ on General Matters of Updater

DCM

DCM

Overview

General limitations on DCM

Restrictions about import/export

Import/Export All from Remote UI

Service mode setting values that can be backed up by DCM

Import/export by service mode (external)

Import/export by service mode (internal)

3. PERIODIC SERVICE

Periodical Service Operation Item

4 Parts Replacement and Cleaning

List of Parts

List of External / Internal Cover

List of Main Units / Parts

Consumable Parts

List of PCBs

List of Solenoids

List of Sensors

List of Motors

List of Fans

List of Switches

List of Clutches

Others

External Covers

Removing the Reader Left Cover

Removing the Reader Front Cover

Removing the Support Cover

Removing the Toner Supply Cover

Removing the Front Cover

Removing the Left Cover

Removing the Inside Base Cover

Removing the Delivery Tray

Removing the Left Rear Cover

Removing the Reader Right Cover

Removing the Reader Rear Cover

Removing the Rear Cover

Removing the Lower Rear Cover

Removing the Rear Right Cover (Upper)

Removing the Rear Right Cover (Lower)

Original Exposure System (Reader)

Removing the Platen Glass

Removing the ADF Scan Glass

Removing the CCD Unit

Cleaning in the CCD unit (Mirror No. 1 – 5)

Removing the Reader Controller PCB

Removing the Reader Assembly

Controller System

Main Controller PCB 1

Main Controller PCB 2

HDD

Laser Exposure System

Removing the Laser Scanner Unit

Image Formation System

Removing the Developing Assembly

Removing the Developing Cylinder

Removing the Transfer Roller

Removing the Separation Static Charge Eliminator

Removing the Waste Toner Container

Removing the Drum Unit

Removing the Toner Supply Assembly

Fixing System

Removing the Fixing Unit

Removing the Fixing Main Unit

Removing the Fixing Film Unit

Removing the Pressure Roller

Pickup Feed System

Removing the Right Cover Unit

Removing the Cassette Pickup Unit 1

Removing the Cassette Pickup Unit 2

Removing the Manual Feed Pickup Roller

Removing the Manual Feed Separation Pad

Removing the Cassette Pickup Roller

Removing the Cassette Feed Roller

Removing the Cassette Separation Roller

Removing the Main Drive Assembly

Removing the No.2 Deliivery Assembly

Removing the No.1 Deliivery Assembly

Removing the No.1 Deliivery Drive Assembly

External Auxiliary System

Removing the DC Controller PCB

Removing the HVT PCB

Removing the Power Supply PCB

Removing the Control Panel Assembly

Removing the Air Filter

5. ADJUSTMENT

Overview

When Replacing Parts

Original Exposure System

Platen Glass

ADF Scan Glass

CCD Unit

Laser Scanner Unit

External Auxiliary System

DC Controller PCB

Controller System

HDD

Main Controller PCB 1

Main Controller PCB 2

TPM PCB

6. TROUBLESHOOTING

Initial Check

Initial check items list

Test Print

Overview

How to View the Test Print

Grid (TYPE=1)

17 gradations (TYPE=2/3)

Solid white (TYPE=4)

Halftone (TYPE=5/6/11/12/13/14)

Solid black (TYPE=7)

Horizontal line (TYPE=8/9/10)

Troubleshooting items

Troubleshooting items

Image Faults

Scattered image at center

Paper Reverse Side Stained with Toner

Stained Leading/Trailing Edge of Paper

Image Transfer Wrong/Text Void

Image Deletion/Blur/Dew Condensation

Too Large Curl

Paper Jam due to Solid Image Printed on Paper with Small Leading-Edge

Margin (1-4 mm)

Thin Paper Jam (63g/m2 or Less)

Version upgrade

Overview

Overview of Version Upgrade

Writing System Software

Download Mode

System Software Components

Note on Download Process

Version Upgrade via SST

Overview

Copying System Software

Connection

Downloading System Software (Assist mode)

Downloading System Software (Single mode)

Formatting HDD

Backup

Version Upgrade using USB memory Storage Device

Relation between SST and USB memory Storage Device

Copying System Software

Connection

Upgrading System Software

Downloading/Writing System Software (Automatic)

Downloading System Software (Confirmation)

Downloading System Software (Overwriting)

Formatting HDD

Backup

Clearing Download File

Download Menu 2

Other Menu

Troubleshooting

Error Code: E753-0001

Optional language support

The number of the installable languages

Optional language selection

Optional language confirmation

Firmware to be exported to USB memory

Startup System Failure Diagnosis

Useful Operations

How to Use Startup System Failure Diagnosis

Startup Failure Analysis Policy

Flow A: Execution Flow for Control Panel Startup Failure

Applicable Condition of the Flow

Flow B: Control Panel Check Flow

Applicable Condition of the Flow

Flow C: Main Controller Analysis Flow

Status Check

Flow D: Power Supply Assembly Check Flow

Applicable Condition of the Flow

Flow E: Execution Flow of Startup System Failure Diagnosis

Status Check

Check item

Reference:

Procedure A: Detailed Procedure of Startup System Failure Diagnosis

Controller Self Diagnosis

Controller Self Diagnosis

Introduction

Overview

Layout Drawing

Basic Flowchart

Operation

Boot System Error Diagnosis

Controller System Error Diagnosis

Restrictions

Version Upgrade via CDS

Overview

Preparation

Overview of Preparation

Setting Sales Company’s HQ

Network Settings

Enabling UGW Link

a. UGW-linked Download and Update (Full-remote Update)

b. UGW-linked Download (Remote Distribution Update)

c. Manual Download and Update (On-site Update from Service Mode)

Deleting Firmware Distribution Schedule

Updating Downloaded Firmware (Applying Firmware)

Deleting Downloaded Firmware

Troubleshooting on Firmware Installation

Information required for Reports

Information required for Service Technicians to Obtain on Site

Information to Report

Debug Logs

Obtaining Log Files

Error Messages

Error Codes

Error Code

How to read an error code

List of Error Codes Likely to Be Displayed

Error Code

Error Codes When Using the UGW-linked Function

Error Codes Not Included in the Error Code List and Remedy for Them

Debug log

Scope of Application

Purpose

Overview

Function Overview

Description of Log to be Collected

Collecting System Information

Collection Destination

Collecting Debug Log (USB memory device)

Uploading Data by SST

Preconditions:

When to Obtain Logs

Operation Check of the Main Controller LEDs

Location of LEDs

Preconditions

Check the lighting of the LDEs on the Main Controller PCB 1

Canon Ir 4235

7. ERROR CODE

Overview

Outline

Outline

Location code

Pickup position code

Points to Note When Clearing MN-CON

Points to Note When Clearing HDD

Error Code

Error Code Details

E000 to E5F6

E602 to E996

Jam Code

Jam Type

Host machine + Cassette Feeding Unit-AF1

Paper Deck Unit-B2

DADF-AG1

Staple Finisher-G1/Booklet Finisher-G1 + External Hole Puncher-B2

Buffer Pass Unit-H1

Inner Finisher-D1 + Inner Hole Puncher-A1

Alarm Code

List of Alarm Code

8. SERVICE MODE

Overview

Overview

Entering Service Mode

Service Mode Menu

Service mode item explanations

Display of Error Code/Alarm Code description

COPIER > OPTION > BODY, Item Segmentation

Security features

Related service modes

Switching Screen (Level 1 < – > 2)

Back-up of service mode

Service Label

The data output of the service data print

Overview

Service Prints and Data File Names That Support File Output

How to Move Service Print Files to a USB Memory Device

How to Move Service Print Files to a PC using the SST

COPIER

DISPLAY

VERSION

USER

ACC-STS

ANALOG

CST-STS

HV-STS

CCD

SENSOR

I/O

Main Body_DC controller (DC-CON>P001 to P016)

Reader (R-CON>P001 to P008)

DADF-AG1 FEEDER > P001 to P009

Staple Finisher-G1/Booklet Finisher-G1 SORTER > P001 to P031

External 2, 2/3, 2/4, 4 Hole Puncher-B2 SORTER > P032 to P037

Inner Finisher-D1/Inner Hole Puncher-A1 SORTER>P001 to P015

ADJUST

AE

ADJ-XY

CCD

LASER

DEVELOP

DENS

BLANK

PASCAL

HV-PRI

HV-TR

FEED-ADJ

CST-ADJ

FIXING

MISC

FUNCTION

INSTALL

CCD

CST

CLEANING

FIXING

PANEL

PART-CHK

CLEAR

MISC-R

MISC-P

SYSTEM

OPTION

FNC-SW

DSPLY-SW

IMG-FIX

IMG-TR

IMG-LSR

IMG-RDR

IMG-MCON

IMG-SPD

CLEANING

ENV-SET

FEED-SW

NETWORK

CUSTOM

USER

CST

ACC

INT-FACE

LCNS-TR

TEST

PG

NETWORK

NET-CAP

COUNTER

TOTAL

PICK-UP

FEEDER

JAM

MISC

JOB

DRBL-1

DRBL-2

LF

FEEDER

DISPLAY

ADJUST

FUNCTION

OPTION

SORTER

ADJUST

FUNCTION

OPTION

BOARD

OPTION

9. INSTALLATION

How to check this Installation Procedure

When Using the parts included in the package

Symbols in the Illustration

Making Pre-Checks

Selecting the Site of Installation

Points to Make Before Installation

Table of Options Combination

Checking the Contents

Unpacking and Installation Procedure

Unpacking the Machine and Removing the Packaging Materials

Installing the Toner Cartridge

Installing the Drum Unit

Installing the Air Filter

Connecting the cord

Setting the Environment Heater Switch (if equipped with the cassette

heater)

Turning ON the Main Power

Stirring Toner

Installing Trays

Setting the Cassettes

Installing the Other Parts

Attaching the Handle Covers

Affixing the seal

Affixing the ADF Label (only for the standard model with an ADF)

Affixing the Labels to the Reader

Affix the Service Book Holder

Installing the Right Cover (Lower) (only when the cassette feeding unit is not

installed)

Securing the Host Machine

Auto Adjust Gradation

Checking the Print Image

Image Position Adjustment

Left Edge Margin Adjustment (1st side)

Left Edge Margin Adjustment (2nd side)

Leading Edge Margin Adjustment (1st side)

Checking the Network Connection

Overview

Checking the Network Connection

Operation Procedure Using Ping

Checking by the Remote Host Address

Network Troubleshooting

Checking Connection of the Network Cable

Operation Procedure Using Ping

Checking the Network Setting of the Host Machine

Checking Network Function on the Main Controller

Printer Model (for Europe)

Points to Note at Installation

Checking the Contents

Contents of Printer Cover-E1

Check Items when Turning OFF the Main Power

Unpacking and Installation Procedure

Unpacking the Machine and Removing the Packaging Materials

Installing the Printer Cover

Heater Kit-K1

Checking the Contents

Check Items when Turning OFF the Main Power

Installation Outline Drawing

Points to Note Before Installation

Installation Procedure

Reader Heater Unit-H1

Checking the Contents

Check Items when Turning OFF the Main Power

Installation Outline Drawing

Points to Note Before Installation

Installation Procedure

Installing the Reader Harness

Installing the Reader Heater

Drum Heater-C1

Checking the Contents

Check Items when Turning OFF the Main Power

Installation Outline Drawing

Confirmation of Heater Driver PCB

Installation Procedure

Paper Deck Heater Unit-C1

Confirmation of Heater Driver PC

Checking Bundled Components

Turning OFF the Main Power Switch

Installation Procedure

Serial Interface Kit-K1/Copy Control Interface Kit-A1

Points to Note at Installation

Checking the Contents

Serial Interface Kit-K1

Copy Control Interface Kit-A1

Check Items when Turning OFF the Main Power

Installation Outline Drawing

Installation Procedure

Preparation before Installation

When Installing the Serial Interface Kit-K1

When Installing the Control Interface Kit-A1

After Installation

Additional Memory Type A (512MB)

Checking the Contents

Pre-Check

Check Items when Turning OFF the Main Power

Installation Outline Drawing

Installation Procedure

Checking after installation

Utility Tray-A2

Points to Note at Installation

Checking the Contents

Installation Outline Drawing

Installation Procedure

When Installing the USB Keyboard

Voice Operation Kit-C2

Points to note when Installing

Checking the Contents

Check Items when Turning OFF the Main Power

Installation Outline Drawing

Installation Procedure

Checking after Installation

Operation Check

When Starting to Use

When Stopping to Use

Copy Card Reader-F1

Points to Note at Installation

Checking the Contents

Copy Card Reader-F1

Copy Card Reader Attachment-B3

Check Items when Turning OFF the Main Power

Installation Outline Drawing

Installation Procedure

Checking after Installation

Voice Guidance Kit-F2

Points to note when Installing

Checking the Contents

Check Items when Turning OFF the Main Power

Installation Outline Drawing

Installation Procedure

Checking the Settings

Operation Check

When Using

When Stopping to Use

Stamp Unit-B1

Checking the contents

Check Items when Turning OFF the Main Power

Installation Outline Drawing

Installation procedure

Operation Check

Document Scan Lock Kit-B1

Points to note before installation

Installation Outline Drawing

Checking the Contents

Check Items when Turning OFF the Main Power

Installation Procedure

Checking after Installation

Inner 2Way Tray-H1

Points to Note When Installing

Checking Bundled Components

Confirmation item of host machine main power supply OFF

Diagrammatical view at the time of the installation

Installation Procedures

Setting after installation

USB Device Port-E3/Multimedia Reader/Writer-A2/A3

Points to Note at Installation

Check Item when Turning OFF the Main Power

Installation Outline Drawing

Checking the Contents

USB Device Port-E3

Multimedia Reader/Writer-A2/A3

Installation Procedure

Installing the USB Device Port

Installing the Card Reader

Installing the Multimedia Reader/Writer

Operation Check

Writing Check

Reading Check

Memory Media Removal

Combination of HDD Options

Points to Note Regarding Data Backup/Export:

Making a Backup of the Data (reference only)

Procedure for Import/Export ALL of User Settings

Backup of MEAP Application

Stop of MEAP Applications, Disabling, Download of Disabled License

Files and Uninstallation

User Authentication Information Registered by SSO-H (Single Sign-ONH)

Backup of User inbox and Advanced Box document data

Removing the HDD

TYPE-1

Checking the Contents

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Disassembling/Assembling and Installing the HDD Removed from the

Host Machine

Installation to the Host Machine

TYPE-2

Checking the Contents

Setting Before Turning OFF the Power

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Installing the Encryption Board

Installing the System Software Using the SST

Checking the Security Version

Checking the Security Mark

Reporting to the System Administrator at the End of the Work

Execution of Auto Adjust Gradation

TYPE-3

Checking the Contents

Setting Before Turning OFF the Power

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Disassembling/Assembling and Installing the HDD Removed from the

Host Machine

Installation to the Host Machine

Installing the System Software Using the SST

Checking the Security Version

Checking the Security Mark

Reporting to the System Administrator at the End of the Work

Execution of Auto Adjust Gradation

TYPE-4

Checking the Contents

Setting Before Turning OFF the Power

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Assembling the Option HDD

Installation to the Host Machine

Installing the System Software Using the SST (Only when installing

HDD Data Encryption & Mirroring Kit)

Checking the Security Version (Only when installing HDD Data

Encryption & Mirroring Kit)

Checking the Security Mark (Only when installing HDD Data Encryption

& Mirroring Kit)

Setting the Mirroring

Reporting to the System Administrator at the End of the Work (Only

when installing HDD Data Encryption & Mirroring Kit)

Execution of Auto Adjust Gradation (Only when installing HDD Data

Encryption & Mirroring Kit)

TYPE-5

Checking the Contents

Setting Before Turning OFF the Power

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Disassembling/Assembling and Installing the HDD Removed from the

Host Machine (First HDD)

Assembling and Installing the Option HDD (Second HDD)

Installation to the Host Machine

Installing the System Software Using the SST (Only when installing

HDD Data Encryption & Mirroring Kit)

Checking the Security Version (Only when installing HDD Data

Encryption & Mirroring Kit)

Checking the Security Mark (Only when installing HDD Data Encryption

& Mirroring Kit)

Setting the Mirroring

Reporting to the System Administrator at the End of the Work (Only

when installing HDD Data Encryption & Mirroring Kit)

Execution of Auto Adjust Gradation (Only when installing HDD Data

Encryption & Mirroring Kit)

TYPE-6

Checking the Contents

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Assembling the Option HDD

Installation to the Host Machine

Installing the System Software Using the SST

Execution of Auto Adjust Gradation

TYPE-7

Checking the Contents

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Assembling and Installing the Option HDD

Installation to the Host Machine

Installing the System Software Using the SST

Execution of Auto Adjust Gradation

TYPE-8

Checking the Contents

Setting Before Turning OFF the Power

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Assembling the Option HDD

Installation to the Host Machine

Installing the System Software Using the SST

Checking the Security Version

Checking the Security Mark

Reporting to the System Administrator at the End of the Work

Execution of Auto Adjust Gradation

TYPE-9

Checking the Contents

Setting Before Turning OFF the Power

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Assembling and Installing the Option HDD

Installation to the Host Machine

Installing the System Software Using the SST

Checking the Security Version

Checking the Security Mark

Reporting to the System Administrator at the End of the Work

Execution of Auto Adjust Gradation

TYPE-10

Checking the Contents

Setting Before Turning OFF the Power

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Assembling the Option HDD

Installation to the Host Machine

Installing the System Software Using the SST

Checking the Security Version (Only when installing HDD Data

Encryption & Mirroring Kit)

Checking the Security Mark (Only when installing HDD Data Encryption

& Mirroring Kit)

Setting the Mirroring

Reporting to the System Administrator at the End of the Work (Only

when installing HDD Data Encryption & Mirroring Kit)

Execution of Auto Adjust Gradation

TYPE-11

Checking the Contents

Setting Before Turning OFF the Power

Check Items when Turning OFF the Main Power

Points to Note at Installation

Installation Outline Drawing

Assembling and Installing the Option HDD (First HDD)

Assembling and Installing the Option HDD (Second HDD)

Installation to the Host Machine

Installing the System Software Using the SST

Checking the Security Version (Only when installing HDD Data

Encryption & Mirroring Kit)

Checking the Security Mark (Only when installing HDD Data Encryption

& Mirroring Kit)

Setting the Mirroring

Reporting to the System Administrator at the End of the Work (Only

when installing HDD Data Encryption & Mirroring Kit)

Execution of Auto Adjust Gradation

Relocating the Machine

Required Articles

Preparation for Relocating the Machine

Work Procedure

Appendix

Service Tools

Special Tools

Oils and Solvents

General Circuit Diagram

General Circuit Diagram (1/11)

General Circuit Diagram (2/11)

General Circuit Diagram (3/11)

General Circuit Diagram (4/11)

General Circuit Diagram (5/11)

General Circuit Diagram (6/11)

General Circuit Diagram (7/11)

General Circuit Diagram (8/11)

General Circuit Diagram (9/11)

General Circuit Diagram (10/11)

General Circuit Diagram (11/11)

General Timing Chart

2 Prints, Continuous, Cassette 1

List of User Mode

Device Information Delivery Settings

Environment Settings

Paper Settings

Display Settings

Timer/Energy Settings

Network

External Interface

Accessibility

Adjustment/Maintenance

Adjust Image Quality

Adjust Action

Maintenance

Function Settings

Common

Copy

Printer

Send

Receive/Forward

Store/Access Files

Secure Print

Web Access

Set Destination

Set Destination

Management Settings

User Management

Device Management

License/Other

Data Management

Detail of HDD partition

Soft Counter List

Soft counter specifications

Soft Counter List

000 to 099

100 to 199

200 to 299

300 to 399

400 to 499

500 to 599

600 to 699

700 to 799

800 to 899

900 to 999

Backup Data

Removal

Removal

Overview

Work Procedure

Canon Ir Adv 4235

Number of pages: 1106.